we specialize in providing full-range OEM & ODM silicone customization services, from concept development and 3D design to mold making, sample testing, and mass production.

With over 100 skilled employees, advanced molding equipment, and a strong R&D team, we help brands and wholesalers turn creative ideas into high-quality market-ready products.

Share your ideas with us — our team will help you develop the perfect silicone product that stands out in your market

Start Your OEM/ODM ProjectTake a look at our past designs and products.

BABY

TEETHING

BABY

TOYS

BABY

FEEDING

PET

PRODUCTS

Your Reliable Partner for Silicone OEM/ODM Customization.

Year Experience

Custom Projects Annually

Custom Projects Annually

By leaving complex projects to a professional team, you will get an efficient, reliable service experience.

Step1

Step1

We begin with understanding your product idea, target market, and required compliance standards. Whether it’s a silicone teether, feeding item, or a custom toy, our team helps refine your concept and provide professional feasibility guidance.

Step2

Step2

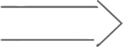

Our design team creates 2D sketches and 3D models based on your approved concept. We help optimize structure, softness, thickness, and safety features to ensure your silicone product meets both aesthetic and functional standards

Step3

Step3

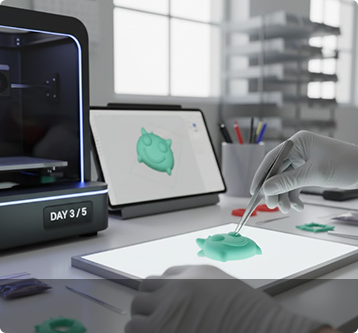

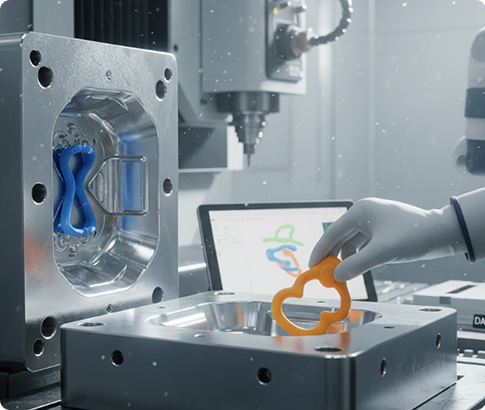

We quickly turn the approved design into real prototypes using silicone material or CNC molds. Customers can evaluate size, hardness, texture, and safety details before moving to mold development.

Step4

Step4

With over 100+ skilled workers and a stable production system, Melikey ensures efficient and consistent manufacturing. All silicone materials are food-grade, BPA-free, and fully compliant with global baby product standards

Step5

Step5

Every batch goes through strict QC, covering raw material safety, hardness test, pulling test, color inspection, and final packaging review. We follow standards required for global baby product export such as EN71, CPSIA, LFGB, FDA, REACH.

Step6

Step6

We provide customized packaging options including color boxes, blister cards, reusable bags, and private-label packaging for branding enhancement. All goods are checked before shipping to guarantee consistency.

When you share your product requirements, our design team will analyze your ideas, create CAD drawings, and provide feasible design proposals. We offer 3D modeling, structure optimization, material recommendations, and convert concepts into practical silicone product designs.

Our designers have over 10 years of experience in the silicone industry and are familiar with global market trends. Even if you only have a simple sketch or a rough idea, we can help you refine it and turn it into a ready-to-produce design.

INQUIRY NOWWith advanced CNC machining and silicone compression molding technology, our engineering team develops high-precision molds that ensure stable mass-production results and long mold lifespan.

We provide rapid prototyping, including 3D printing, sample testing, and structural verification. This helps you confirm product details such as hardness, fit, thickness, and overall performance before mass production.

Every mold and prototype goes through dimensional checks, tolerance reviews, and functional testing. This ensures your final silicone product meets quality standards and market expectations.

INQUIRY NOWReply within

Quotation within

Prototyping

Mass productior

Our silicone products are manufactured under strict quality management systems, meeting global safety and

compliance standards including EN71, CPSIA, FDA, LFGB...

OFrequently Asked Questions

The more detailed, the better the final result.

Exact time depends on product complexity.

Yes. We offer 3D-printed prototypes and silicone sampling for structure and size confirmation

We use 100% food-grade silicone, BPA-free, non-toxic, LFGB & FDA compliant—safe for babies and pets

MOQ starts from:

(Depending on size and mold cavities)

Yes. We follow strict QC procedures including:

Looking forward to your inguiry through Email or Whatsapp. We will try our best to get back to you within 24 hours.

We also appreciate lf you have any suggestion about our products or service. We are always here.